What It Takes To Make A Bond Suitcase

Behind the craft with Globe-Trotter

Planes, trains, subs and speedboats: James Bond knows how to travel, switching from black tie to tactical kit with ease. Accompanying him in recent years is his Globe-Trotter luggage. Here we take a closer look at what it takes to make bags for a licensed troubleshooter.

Globe-Trotter has been producing luxury cases, bags and accessories since it was founded in 1897. Each piece is handmade at its Hertfordshire workshop using methods and machinery that date back to the Victorian era. The company has a long history of creating bespoke pieces for clients; Scott reached the Antarctic with his vented vulcanised fibreboard luggage. Sir Edmund Hilary set off to scale Mount Everest with his trusted Globe-Trotter case and Sir Winston Churchill was also a fan. Queen Elizabeth II was given a Globe-Trotter case for her honeymoon which she still uses today.

Globe-Trotter first started its relationship with 007 on 2012’s Skyfall. During production, the design team was asked to collaborate with the film’s armoury department to create a specialised case for the assassin Patrice. After putting a bullet in Bond’s shoulder in Morocco, Patrice arrives in Shanghai with what appears to be a sleek black attaché. On the 67th floor of a Shanghai skyscraper, he deconstructs the case and from it methodically assembles a sniper rifle and glass cutter. Taking inspiration from Scaramanga’s untraceable weapon in The Man From The Golden Gun, the bag that was created is made up of functional elements. Its handle is the rifle’s telescopic sight and each part of the construction fits together to make the gun.

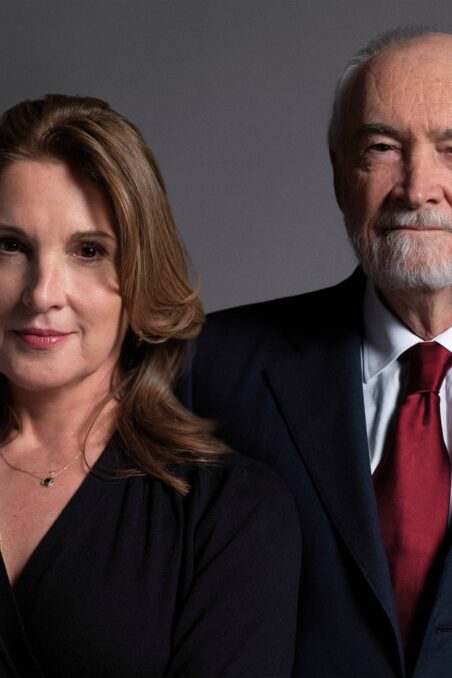

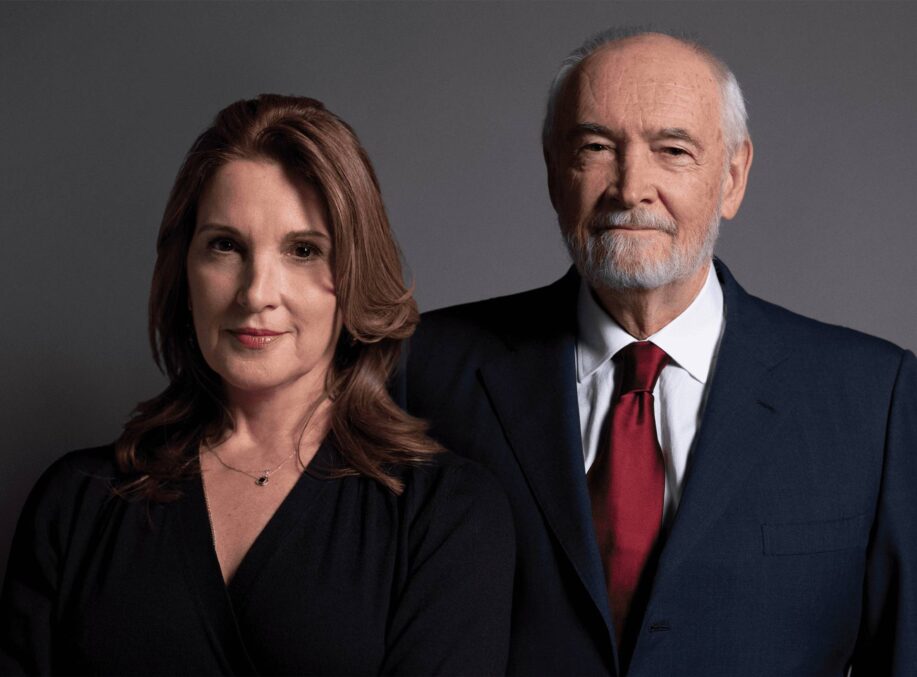

The relationship continued in Spectre when Bond and Madeleine Swann travel to visit Blofeld in the Moroccan desert with a Globe-Trotter Original suitcase. This traditional style is a remake of one of the company’s early designs, and was made for the film in brown vulcanised fibreboard with black corners – a colourway intended to harmonise with the scene’s desert setting.

Globe-Trotter cases are again seen on screen in Bond’s latest mission. In No Time To Die, James and Madeleine arrive at their hotel in Matera with a set of Globe-Trotter suitcases and a holdall stashed in the boot of the DB5. Their luggage is then carried to their room by porters. One of the pieces is a pinstripe carbon fibre case with graphite leather details; the other two are classic green vulcanised fibreboard cases with black leather straps and corners.

You’ll find vulcanised fibreboard in every Globe-Trotter range. As strong as leather and as light as aluminum, this unique material was invented in Britain in the 1850s and patented by Globe-Trotter in 1901. The Bond suitcase is made with an eight point process. A state of the art CNC machine cuts out the perimeter and drills the holes for the rivets out of the vulcanised fibreboard. Each panel is expertly moulded into shape using a method patented by Globe-Trotter in 1901. Then components are attached by hand using the traditional hammer and nail technique for handles, and a foot pedal riveting machine for locks and attaching both side panels and corners. The signature Globe-Trotter leather corners are moulded on Victorian press machines over a period of five days to ensure optimum strength and form.

Handles are made entirely by hand to include the core materials that are bonded and pressed for 48 hours before construction can begin. Next a fabric lining is cut to size, glued and inserted by hand for a seamless finish. Steel lipping is cut, formed and attached by hand to the suitcases for optimum strength and form. To finish, each Globe-Trotter case is examined closely and quality-checked before packaging and leaving the factory.

Find 007 x Globe-Trotter pieces inspired by their film counterparts at 007Store.com. For the 60th Anniversary, the company has created new designs in navy vulcanised fibreboard and pieces decorated with Maurice Binder’s iconic Dr. No dots here.